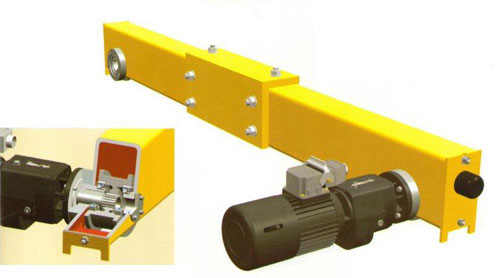

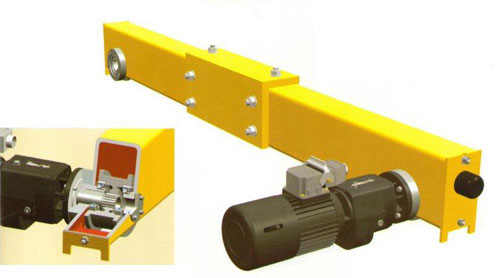

Features :

- » Available for

single and double girder cranes

- »

Modular box type construction

- »

Completely machined fabrication giving perfect alignments and tolerances

- » Forged

wheels in CK 45 material or SEW IRON 800/2

- »

All drive units from 85 SEW Nord

- »

Gear drives directly coupled to wheels through hollow shaft

-

» Soft start/stop feature is standard

- » AC Disc brakes are

fitted as standard

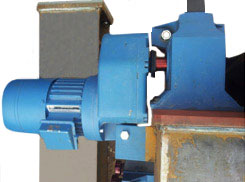

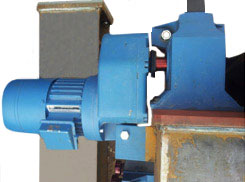

A) Drive Wheel Assembly

:

Features:

A) Drive Wheel Assembly

:

Features:

- »

Modular wheel blocks in different sizes and capacities

- » Steel

fabricated and completely machined bodies

- » Forged

wheels in CK 45 material / SG IRON 800/2

- »

All Drive units from SEW NORD

- »

Gear drives directly coupled to wheels through hollow shaft

- » AC disc brakes are

fitted as standard

-

» Provided with or without gear drives

B) Crane Wheel Assembly

:

B) Crane Wheel Assembly

:

Presently most of the Crane manufacturers are using En 9 or En 8 material forgings for crane

wheels. The wheels are manufactured in forging due to which we have to pay @ 30% more cost

towards the basic Raw Material & this additional material we need to remove in machining by

investing more machining time. Lead time for forgings is min 4 to 5 weeks from the date of order

& 1 more week for machining, heat treatment & other finishing (e.g. bore grinding). It

means we have to plan the material before 5 to 6 weeks.

In case of En 24, we need to have few more days for machining time due to high hardness as

compare to En 9 To avoid high procurement time & heavy machining, we have developed these

Crane wheel in SGI 800/2 material. Main property of this material is self lubrication & high

strength.

Since these are castings, the delivery period of the material will be reducing to 3 weeks

against of forging 5 to 6 weeks. Along with this we can save 15% to 20% in overall cost. We are

giving the test certificate for every wheel with traceability for wheel No. The report will

contain UT & actual hardness of wheel along with physical & chemical of material.

Sizes of the wheel is available from 150 mm to 630 mm (As per customer's requirement)

A comparison chart for En 9 & SGI 800/2 is given below for your reference.

C) Gearbox Assembly :

C) Gearbox Assembly :

+91-9369-222-000

+91-9369-222-000

+971-55-587-5704

+971-55-587-5704